Thermoset Injection Molded Electrical Component Housing

At MCM Composites, LLC, we offer vast knowledge in the precision manufacturing of electrical component housings using injection molding processes. Our experience in the electronics industry includes the molding of housings with multiple inserts, as well as secondary operations such as machining and assembly to achieve the final product

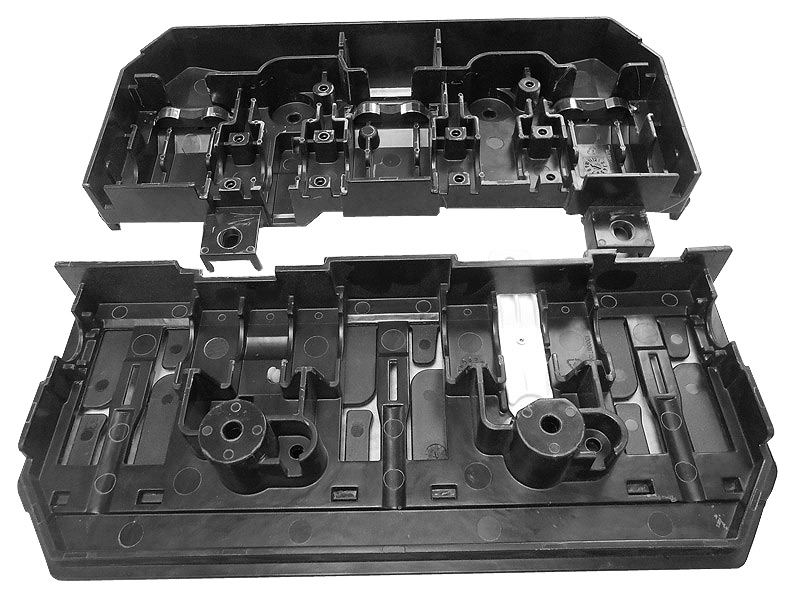

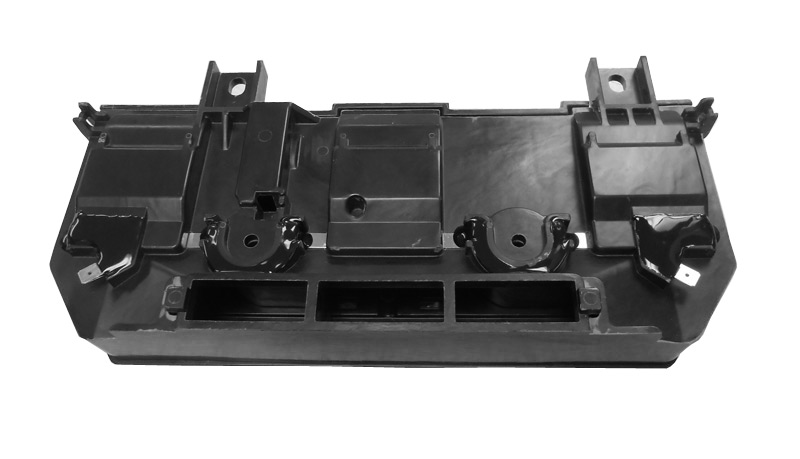

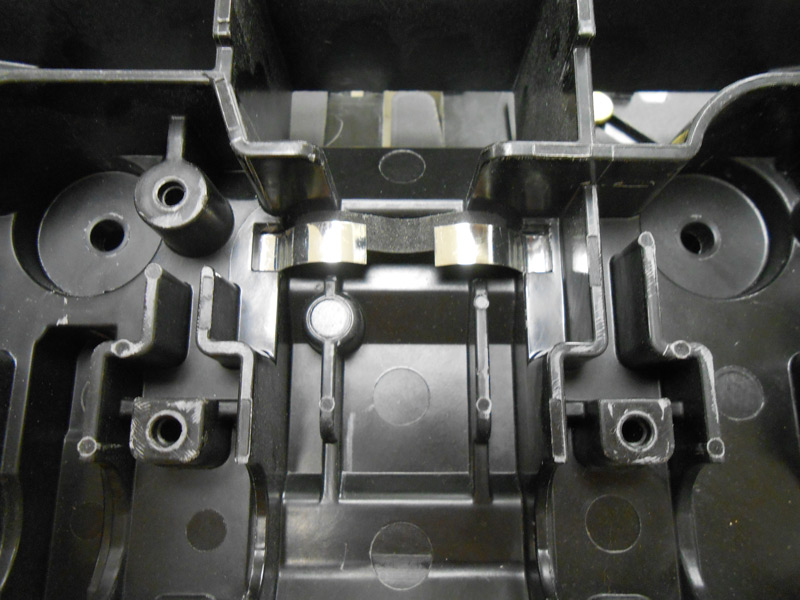

An electronics customer required a stab housing with overall dimensions of 10″ x 5″ x 0.125″ and tolerances as close as + 0.005″. The housing consisted of two halves, each having 5 different inserts included. Using thermoset injection molding with BMC, the parts were produced according to exact customer requirements. The halves were then de-flashed, deburred, and jet blasted. Additional internal features were machined, while metal contacts were installed throughout the body for assembly. Each housing underwent visual and dimensional inspection in order to maintain strict quality control.

In less than 2 weeks, a total of 3,000 units were produced. With over 10 different inserts per unit, the stab housing represented one of our most complicated manufacturing projects to date. Thanks to the work and expertise of our team, combined with a stringent quality inspection process, our customer was extremely pleased with our work.

Electrical Component Project Highlights

Stab Housing

Thermoset Injection Molding, Machining, Assembly

De-flashing, Deburring, Jet Blasting

10″ x 5″ x 0.125″

±0.005 inches

BMC

Dimensional Inspection, Visual Inspection

Electronics

3,000

2 Weeks