Thermoset Compression Molded Chair for the Medical Industry

We’ve worked in a variety of industries that require assembly components to be made with high strength materials such as Sheet Molded Compound (SMC). At MCM Composites, LLC, our work with SMC also includes years of expertise in compression molding and machining for the medical industry.

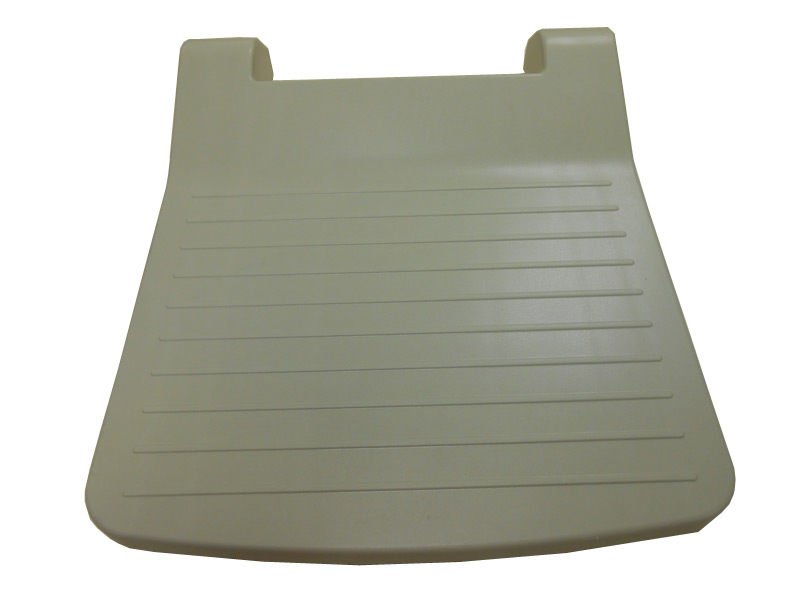

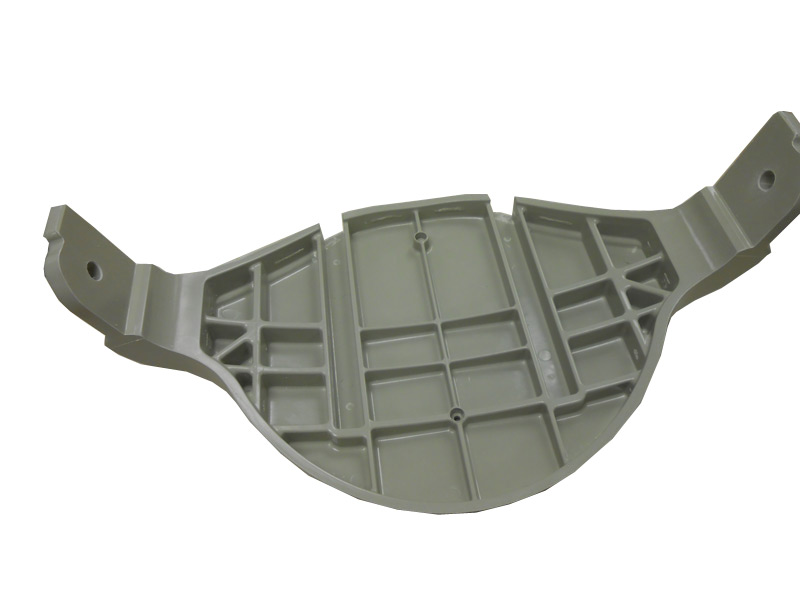

Our medical client required thermoset compression molding for a set of 4 parts to be used as components for an individual chair lift design. Since this chair would require high strength materials to support each patient, we chose SMC for the job. The components were molded in various sizes up to 19″ in length and 6″ high with + 0.005″ tolerances. Each chair part was then de-flashed and deburred after the molding process. Additional features such as fastener holes were drilled and finished using automated machining. All chair components where examined visually, then confirmed with dimensional and gage inspection prior to shipping.

Our work with high strength materials such as SMC for these chair components included both molding and machining operations. In less than 1 week, we were able to produce a total of 12,000 units. The project was a success and our customer was pleased with our manufacturing quality. Thanks to the knowledge and expertise of our team, we continue to work with high strength materials for numerous industries today.

Molded Bruno Chair Project Highlights

Individual Living Chair Lift Components

Thermoset Compression Molding – 4 Parts Automated Machining

De-flashing and Deburring

Various Sizes Ranging from 19″ in Length to 6″ High

±0.005 inches

Sheet Molded Compound (SMC)

Dimensional Inspection, Visual Inspection, Gage Inspection

Medical

12,000

5 Days