Thermoset Injection Molding Services

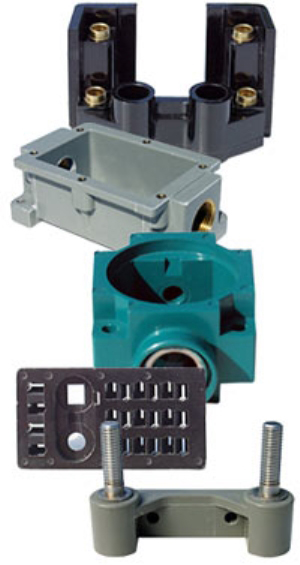

MCM Composites, LLC specializes in manufacturing thermoset injection molded parts, especially suited for the electronics and appliance industries. Through precision injection molding, we produce intricate as well as large parts made from phenolics, alkyds, polyester (both BMC and SMC), carbon fiber compounds, and composite material. The weight of these parts ranges from 0.1 grams to 10 pounds.

Our custom mold shop is equipped with a range of electrical and hydraulic injection molding presses with tonnage capacities ranging from 75 tons to 500 tons. These molding presses are equipped with degas sequence, gate cut sequence, core pull, and runnerless injection compression systems.

MCM’s manufacturing plant also houses a quality lab, tool repair shop, plus cool room for storing perishable raw materials and customers’ molds. Our fully equipped tool shop enables us to design unique tools to create molds as well as offer repair and maintenance services for customers’ molds. We work in conjunction with our customers, toolmakers, and tool designers to construct initial 3D models of the products. In-house tooling capabilities assist us to optimize product quality, maximize production efficiency, and minimize product cost. Molded parts, manufactured from our specially formulated high-strength, thermoset composites, can be used as economical alternatives to stamped or formed parts, aluminum extrusions, and other machined components.

- Superior mechanical performance at temperatures as high as 260°C

- Multi-piece part assemblies into a single mold

- Secondary services such as tapping, drilling, coating and multi-piece assembling

Our Injection Molding Capabilities

Single-cavity, Multi-cavity, Family, and Insert

0.1 grams to 10 lbs

18.7″ x 20.7″ to 46.1″ x 46.1″

ISO 9001:2015 Registered

±0.0015 inches

75 tons to 500 tons

Thermoset Injection Molding Advantages

- Dimensional stability

- Mechanical strength

- Cost advantage vs machined metal parts

- Creep resistance

- Electric insulating qualities

- Thermal insulating qualities

- Sound dampening

- Low expansion coefficient

- Low flammability

- Low fluid absorption (water or chemicals)

- No corrosion

Additional Details

- Alkyd

- Carbon Fiber Compounds

- Melamine-Phenolics

- Phenolics

- Polyester (Both BMC and SMC)

- Melamine

- Epoxies

- Vinyl Ester (Both BMC & SMC)

- Deflashing

- Drilling

- Epoxy

- Gluing

- Machining

- Metal Insertion

- Metallizing

- Painting

- Post bake

- Potting

- Tapping

- Tooling engineering staff with experience in all mold types with many design characteristics, such as rising islands, gate cutoff, and cold manifold.

- Design each tool to create a mold to optimize product quality, maximize production efficiencies, and minimize product cost.

- Fully equipped tool shop to repair and maintain all of our customers’ molds.

- Regular maintenance of molds. Each mold reviewed after each production run.

- Appliance

- Aerospace

- Batteries

- Defense

- Electrical

- Food & Beverage

- Fracking & Oil Field

- Housewares

- Lighting

- Medical

- Outdoor Grills

- Park & Recreation

- Pumps

- Restaurant

AutoCAD, Fusion 360, SolidWorks, MasterCAM, SpinFire

Ready to get started?

"*" indicates required fields